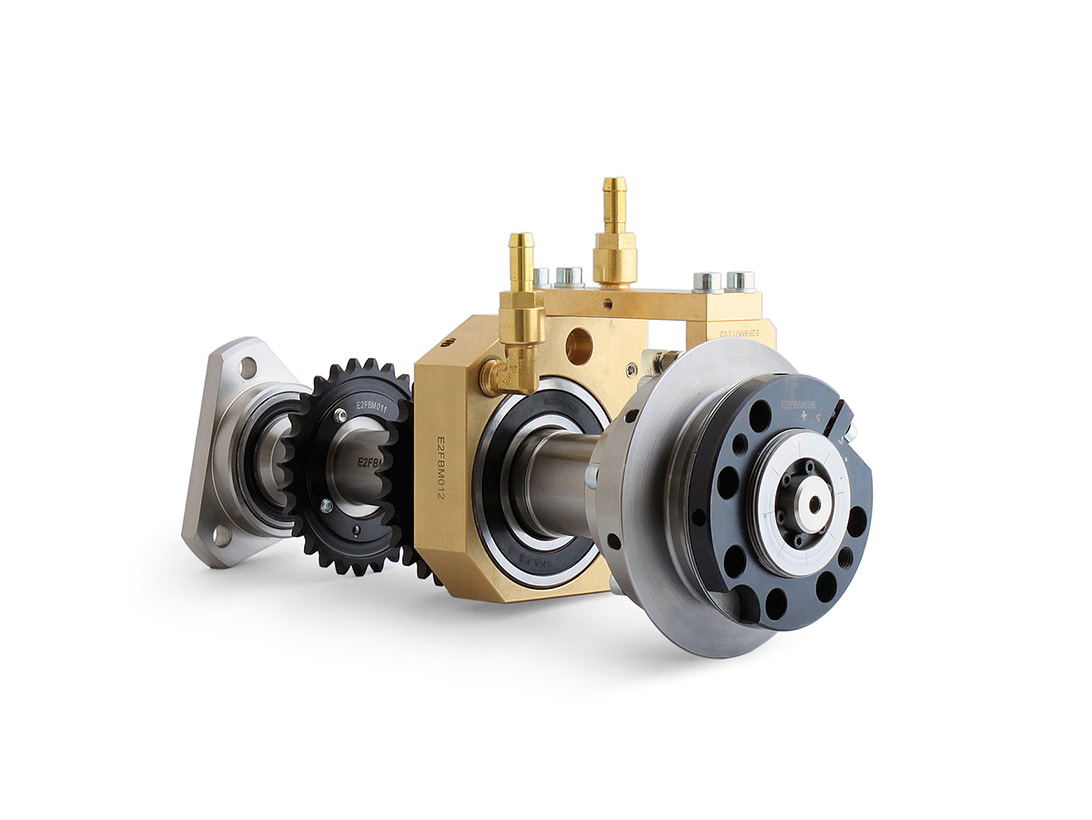

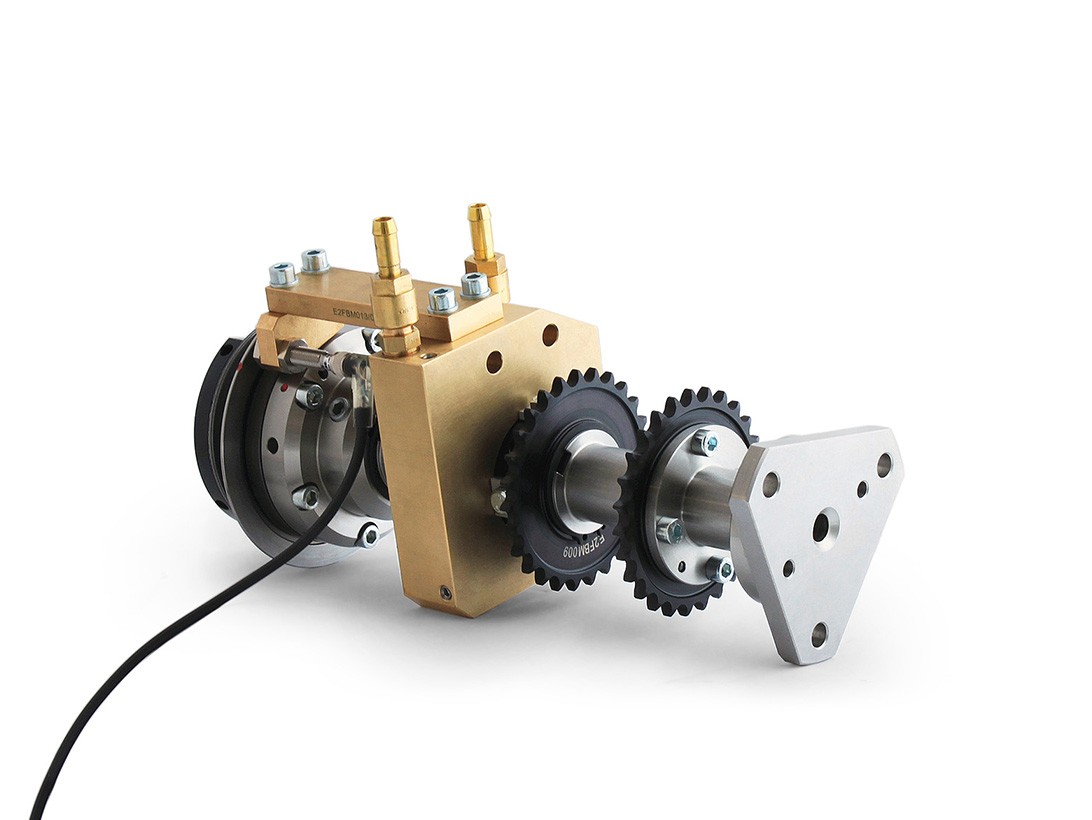

Our ratchet clutch connects the feeder gearbox with the chain. Through the elongated drive shaft, the ratchet clutch is placed away from magnetic field of the welding current. Therefore, there is no overheating and it allows higher welding frequencies.

The clutch unit can be removed independently without having to disassemble the chain guides nor the lower welding arm. The down-time during the service work can be reduced considerably.

The clutch is approx. 30% lighter in weight than the original clutch and therefore relieves stain on the gearbox.

The clutch upgrade can be used on the FBB400/420, FBB500/540, FBB5501, FBB5502, MKII, FBB5600 and FBB5700.

Advantages

- No heating up

- High welding frequencies possible

- No air cooling necessary

- Monitored electrically

- Easy to disassemble & simple maintenance work

- No additional parts or tools for installation necessary